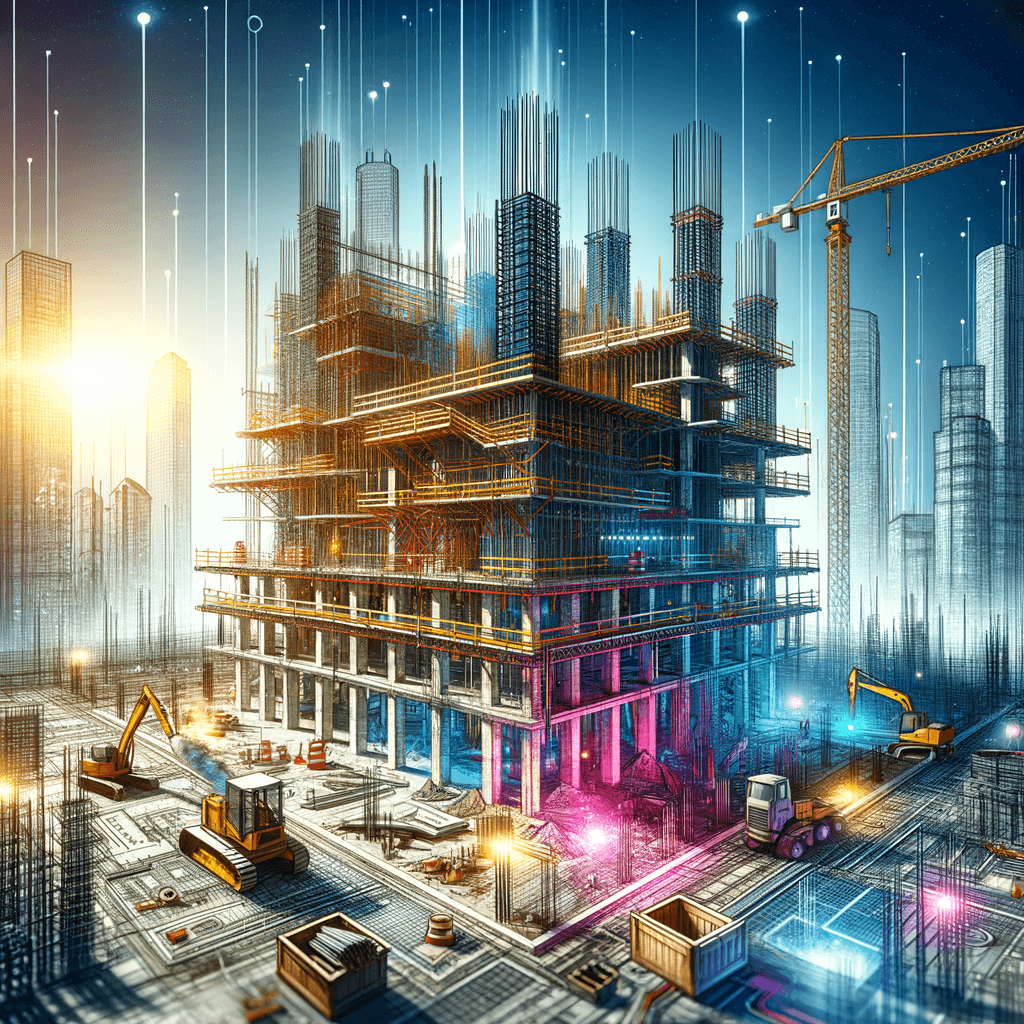

The Impact of Concrete Formwork Systems on Modern Construction Projects

By Total Care Concrete Wed Nov 19 20257 minutes

Understanding Concrete Formwork: The Backbone of Precision

Concrete formwork is a temporary or permanent mold into which concrete is poured to achieve the desired structural shape. Its selection and implementation directly influence the quality, speed, and cost-effectiveness of a construction project, making it a pivotal consideration for builders, architects, and property owners.“Well-designed formwork is the silent partner in every successful concrete structure.”

Types of Concrete Formwork Systems and Their Unique Advantages

- Traditional Timber Formwork: Economical and adaptable, ideal for bespoke or intricate shapes but labor-intensive.

- Engineered Modular Formwork: Prefabricated panels made from steel, aluminum, or plastic, offering speed, reusability, and consistent finishes.

- Slip Formwork: Continuous pouring for tall, vertical structures like silos and towers, minimizing joints and boosting structural integrity.

- Stay-in-Place Formwork: Integrated into the structure, enhancing insulation and reducing labor post-pour.

- Flexible Formwork: Utilizes fabric or flexible materials for free-form architectural designs, expanding creative possibilities.

Innovations in Formwork: Raising the Bar for Efficiency and Safety

Recent advancements in formwork technology are transforming how concrete is shaped and supported. From self-climbing systems to integrated sensors for real-time monitoring, these innovations reduce labor, accelerate project timelines, and enhance site safety. The integration of lightweight composites and digital modeling also allows for precise planning and minimal material waste.Comparing Formwork Systems: Which Solution Fits Your Project?

Selecting the right formwork system depends on factors such as project scale, architectural complexity, budget, and environmental considerations. The following table compares key characteristics of popular formwork systems, helping stakeholders make informed decisions.| System | Material | Best Use Case | Reusability | Labor Intensity |

| Timber | Wood | Custom, small-scale | Low | High |

| Modular | Steel/Aluminum/Plastic | Large, repetitive | High | Low |

| Slip | Steel | Tall, continuous | Moderate | Moderate |

| Stay-in-Place | Composite/Plastic | Insulated walls | Permanent | Low |

| Flexible | Fabric | Organic shapes | Low | Moderate |

How the Right Formwork Elevates Project Outcomes

Efficient formwork selection not only streamlines construction but also improves concrete surface quality, reduces rectification costs, and ensures compliance with safety standards. Long-term, it impacts durability and maintenance needs, safeguarding both investment and reputation.“Investing in advanced formwork is investing in the longevity and aesthetics of your structure.”

Choosing a Formwork Partner: What Should You Look For?

The expertise of your formwork provider can make or break project timelines and outcomes. Look for teams with a track record in your project type, robust safety protocols, and a portfolio of innovative solutions tailored to your specific requirements.- Extensive project experience and technical know-how

- Commitment to safety and regulatory compliance

- Access to modern formwork technologies

- Flexibility to accommodate unique architectural visions

- Responsive support throughout the project lifecycle