The Impact of Concrete Formwork Innovations on Modern Construction

By Total Care Concrete Wed Oct 15 20257 minutes

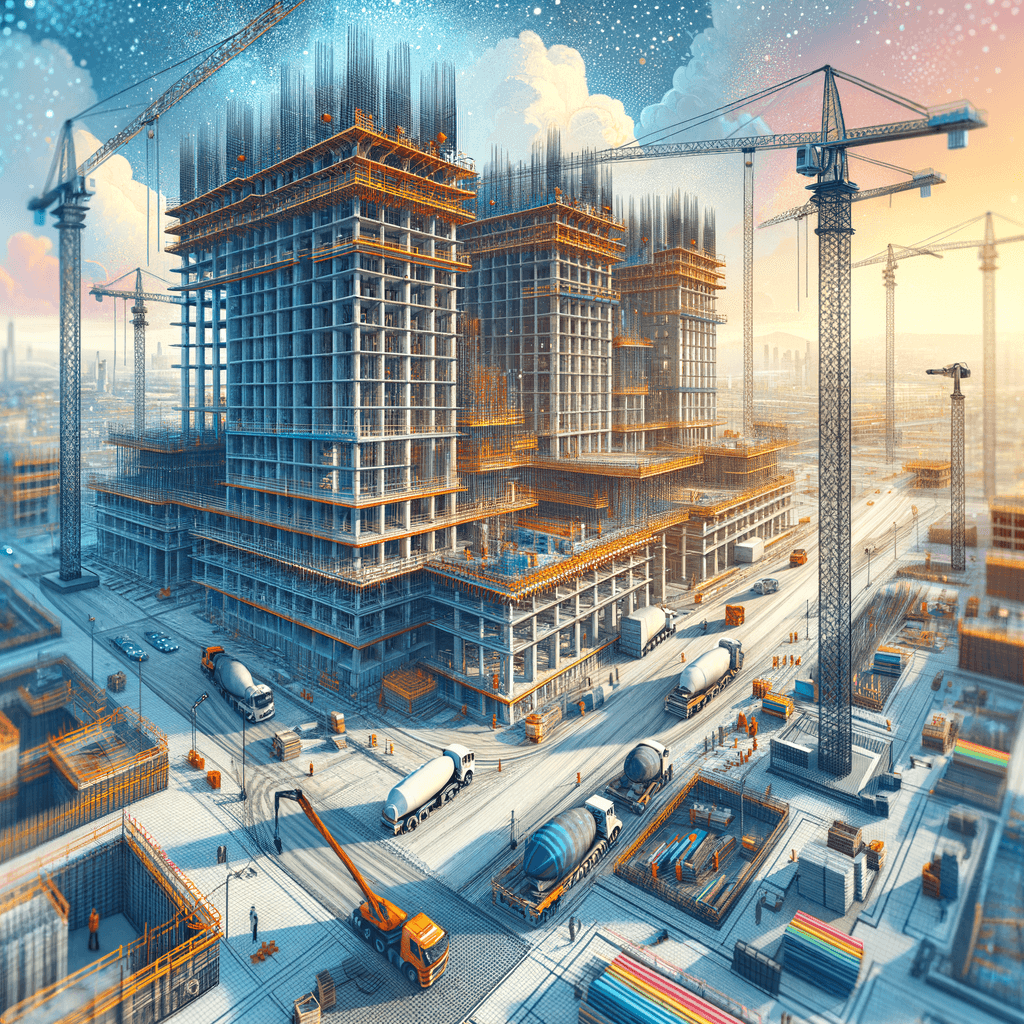

Understanding Concrete Formwork: The Backbone of Precision

Concrete formwork serves as the temporary or permanent mold into which concrete is poured, dictating the shape, structural integrity, and surface finish of the final product. As construction projects demand more intricate designs and accelerated timelines, the evolution of formwork technology has become a pivotal factor in achieving superior outcomes.“A well-designed formwork system is the silent partner in every successful concrete project.”

Types of Innovative Formwork Systems

Modern construction sites are moving beyond traditional timber formwork, embracing advanced systems that offer greater efficiency and adaptability. These innovations are transforming how contractors approach complex architectural demands and tight project schedules.- Modular Panel Formwork: Prefabricated panels that can be quickly assembled and reused across multiple projects.

- Climbing Formwork: Mechanized systems ideal for high-rise structures, allowing formwork to move upward as the building rises.

- Flexible Formwork: Utilizes high-strength fabrics to create unique, organic shapes not possible with rigid molds.

- Insulating Concrete Forms (ICFs): Dual-purpose forms that remain in place, providing both structure and thermal insulation.

Comparing Formwork Materials: Durability, Cost, and Sustainability

Selecting the right formwork material is crucial for balancing project costs, durability, and environmental impact. Each material presents unique advantages depending on the application and desired finish.| Material | Durability | Reusability | Cost | Sustainability |

| Timber | Moderate | Low | Low | Biodegradable |

| Steel | High | Very High | High | Recyclable |

| Aluminum | High | High | Medium | Recyclable |

| Plastic | Moderate | High | Medium | Recyclable |

| Fabric | Variable | Variable | Low | Low environmental impact |

Key Benefits of Advanced Formwork in Construction Projects

The adoption of innovative formwork systems addresses several pain points commonly faced by contractors and property developers, from project delays to inconsistent finishes. By leveraging these advancements, stakeholders can achieve higher quality results with improved efficiency.- Accelerated construction timelines due to faster assembly and removal.

- Superior surface finishes, reducing the need for additional treatments.

- Lower labor costs through reduced manual handling and simplified processes.

- Enhanced safety with lighter, ergonomic components and integrated safety features.

- Reduced material waste and environmental impact, supporting green building goals.

Challenges and Solutions in Implementing New Formwork Technologies

Despite the clear advantages, integrating new formwork systems into established workflows can pose challenges. Issues such as initial investment, workforce training, and compatibility with existing designs require strategic planning and open communication between all parties involved.“Innovation in formwork is not just about technology—it's about collaboration and adaptability on the job site.”