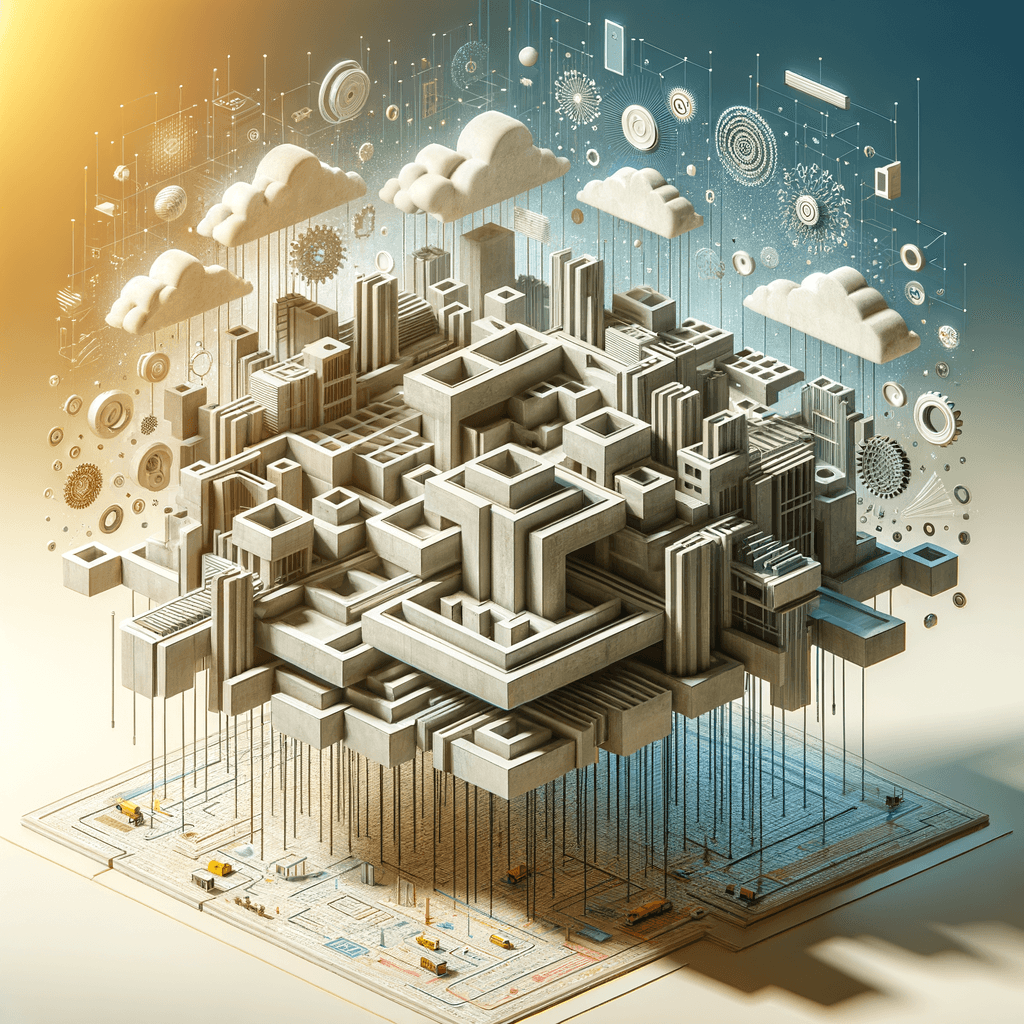

Innovative Concrete Formwork Systems: Shaping the Future of Construction

By Total Care Concrete Sat Nov 01 20257 minutes

Understanding Concrete Formwork: The Backbone of Structural Precision

Concrete formwork serves as the temporary or permanent mold into which concrete is poured, determining the final shape, surface finish, and structural integrity of the construction element. The evolution of formwork technology directly influences build quality, speed, and safety, making it a critical consideration for contractors and architects alike.“Formwork is the silent architect behind every concrete masterpiece, dictating both form and function.”

Types of Modern Concrete Formwork Systems

With the advent of advanced materials and engineering, the range of formwork systems has expanded far beyond traditional timber. Modern projects benefit from modular, reusable, and high-precision solutions that streamline construction while reducing waste and labor costs.- Timber Formwork: Customizable but labor-intensive, ideal for unique shapes or small-scale projects.

- Steel Formwork: Highly durable and reusable, offering excellent dimensional accuracy and smooth finishes.

- Aluminum Formwork: Lightweight yet robust, enabling rapid assembly and disassembly for repetitive layouts.

- Plastic Formwork: Modular, easy to clean, and suitable for complex geometries or decorative elements.

- Stay-in-Place Formwork: Integrates permanently with the structure, often used for foundation walls or precast elements.

“Selecting the right formwork system is a strategic decision that can transform a project's timeline and budget.”

Key Benefits of Advanced Formwork Solutions

Innovative formwork systems are designed to address the pressing demands of modern construction—speed, safety, sustainability, and precision. Their adoption can directly impact project profitability and long-term performance.- Accelerated Construction Schedules: Prefabricated and modular systems enable faster assembly, minimizing project delays.

- Enhanced Safety: Engineered formwork reduces manual handling and risk of onsite accidents.

- Superior Surface Quality: Precision molds create smoother finishes, reducing the need for post-pour corrections.

- Reduced Material Waste: Reusable and recyclable systems support green building initiatives.

- Labor Efficiency: Simplified installation processes lower labor requirements and training needs.

“Investing in advanced formwork is investing in the future resilience and aesthetics of your concrete structures.”

Comparing Formwork Systems: Performance and Cost Considerations

Choosing a formwork system involves balancing initial costs with long-term benefits such as reusability, labor savings, and finish quality. The table below outlines key differences among popular systems to help guide your selection process.“The optimal formwork system is the one that aligns with your project's unique goals, constraints, and design vision.”

| Formwork Type | Durability | Reusability | Surface Finish | Typical Applications |

| Timber | Low | Low | Variable | Custom shapes, small projects |

| Steel | High | High | Excellent | Large-scale, repetitive elements |

| Aluminum | Medium | High | Good | Residential, mid-rise buildings |

| Plastic | Medium | Medium | Good | Decorative, complex forms |

| Stay-in-Place | High | N/A | Good | Foundations, precast walls |

Future Trends: Digitalization and Sustainability in Formwork Design

Emerging technologies like Building Information Modeling (BIM), 3D printing, and smart sensors are revolutionizing formwork design and management. These innovations promise even greater precision, reduced errors, and the ability to create complex architectural forms with less environmental impact.“The integration of digital tools with formwork systems marks a new era of efficiency and creativity in concrete construction.”

Is Your Next Project Ready for Next-Generation Formwork?

As the construction industry evolves, so too must the tools and techniques we use. Adopting innovative formwork systems can be the key to overcoming project challenges, achieving ambitious designs, and staying competitive. What experiences have you had with advanced formwork solutions? Which technologies are you most interested in exploring for future projects? Share your thoughts and join the conversation below.“Progress in concrete construction starts with rethinking the molds that shape our built environment.”