Cold Weather Concrete Pouring: Techniques for Quality and Durability

By Total Care Concrete Thu Dec 04 20258 minutes

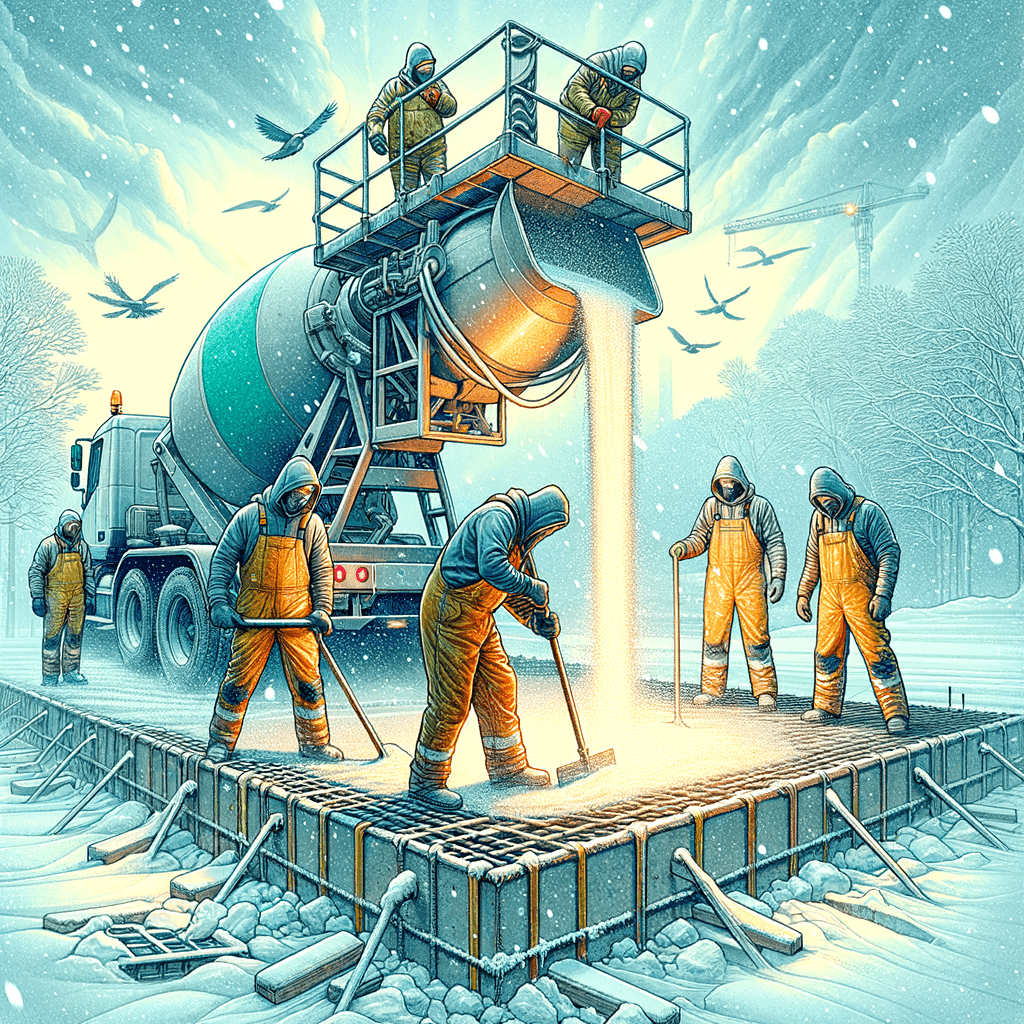

Understanding the Challenges of Cold Weather Concrete Pouring

Pouring concrete in cold climates presents unique challenges, from delayed setting times to increased risk of cracking and reduced strength. As temperatures drop, hydration slows and water in the mix can freeze, potentially leading to structural weaknesses. For contractors and homeowners in regions with harsh winters, addressing these issues is critical to achieving durable, high-performance results.“Success in winter concrete work hinges on preparation, adaptation, and strict adherence to temperature control.”

Essential Pre-Pour Planning for Winter Conditions

Preparation is the cornerstone of any successful cold weather concrete pour. Assessing weather forecasts, ensuring material readiness, and planning for on-site temperature control can make the difference between a resilient slab and one prone to early failure.- Evaluate forecasted temperatures for the pour window and curing period.

- Store aggregates and cement in heated, dry environments to prevent moisture absorption and freezing.

- Preheat forms and reinforcement to minimize temperature shock upon concrete placement.

- Organize insulated blankets, heated enclosures, or ground thawing equipment ahead of time.

Optimizing Concrete Mix Design for Cold Temperatures

Adjusting the concrete mix is vital to counteract the effects of cold weather. Specialized admixtures and mix modifications can accelerate setting, enhance early strength, and reduce the risk of frost damage during the initial cure.- Increase cement content to promote faster hydration.

- Use hot water in the mix to raise initial concrete temperature.

- Incorporate non-chloride accelerators to speed up set time without compromising rebar integrity.

- Select air-entraining agents to improve freeze-thaw resistance.

Best Practices for Pouring and Placing Concrete in Winter

Timing and technique are critical when placing concrete in low temperatures. Rapid placement, efficient finishing, and immediate protection are all essential to maintaining workability and preventing thermal shock.- Limit pour size to ensure timely placement and finishing.

- Avoid placing concrete on frozen ground or ice to prevent uneven curing and slab movement.

- Use windbreaks and heated enclosures to maintain ambient temperatures above 40°F (4°C).

- Monitor concrete temperature with probes to ensure compliance with project specifications.

Effective Curing Methods for Cold Weather Concrete

Proper curing is often the most overlooked aspect of cold weather concreting, yet it is vital for strength development and crack prevention. Without adequate heat and moisture retention, even the best mix can underperform.- Cover freshly poured surfaces with insulated curing blankets immediately after finishing.

- Utilize heated enclosures or temporary shelters to maintain consistent curing temperatures.

- Avoid premature removal of insulation—wait until concrete reaches at least 500 psi compressive strength.

- Continue temperature monitoring throughout the curing period.

“Curing in cold weather is not just about keeping concrete warm; it's about ensuring hydration continues undisturbed for optimal strength.”

Common Mistakes to Avoid in Winter Concrete Projects

Even experienced professionals can overlook critical details during winter pours. Awareness of frequent pitfalls can help you avoid costly repairs and ensure lasting performance.- Pouring on or against frozen subgrade, leading to uneven settlement.

- Neglecting to adjust mix design for lower temperatures.

- Removing insulation too early, risking thermal cracking.

- Underestimating the importance of continuous temperature monitoring.

Cost and Timeline Considerations for Cold Weather Concreting

Cold weather pours often require additional resources, which can impact both budget and project schedule. Understanding these variables helps set realistic expectations and ensures a smoother construction process.| Factor | Impact |

| Heated enclosures & blankets | Increases material and labor costs |

| Accelerating admixtures | Adds to mix expense |

| Extended curing periods | Lengthens project timeline |

| Weather delays | Potential for schedule disruptions |