Cold Weather Concrete Pouring: Techniques, Challenges, and Best Practices

By Total Care Concrete Sun Nov 16 20257 minutes

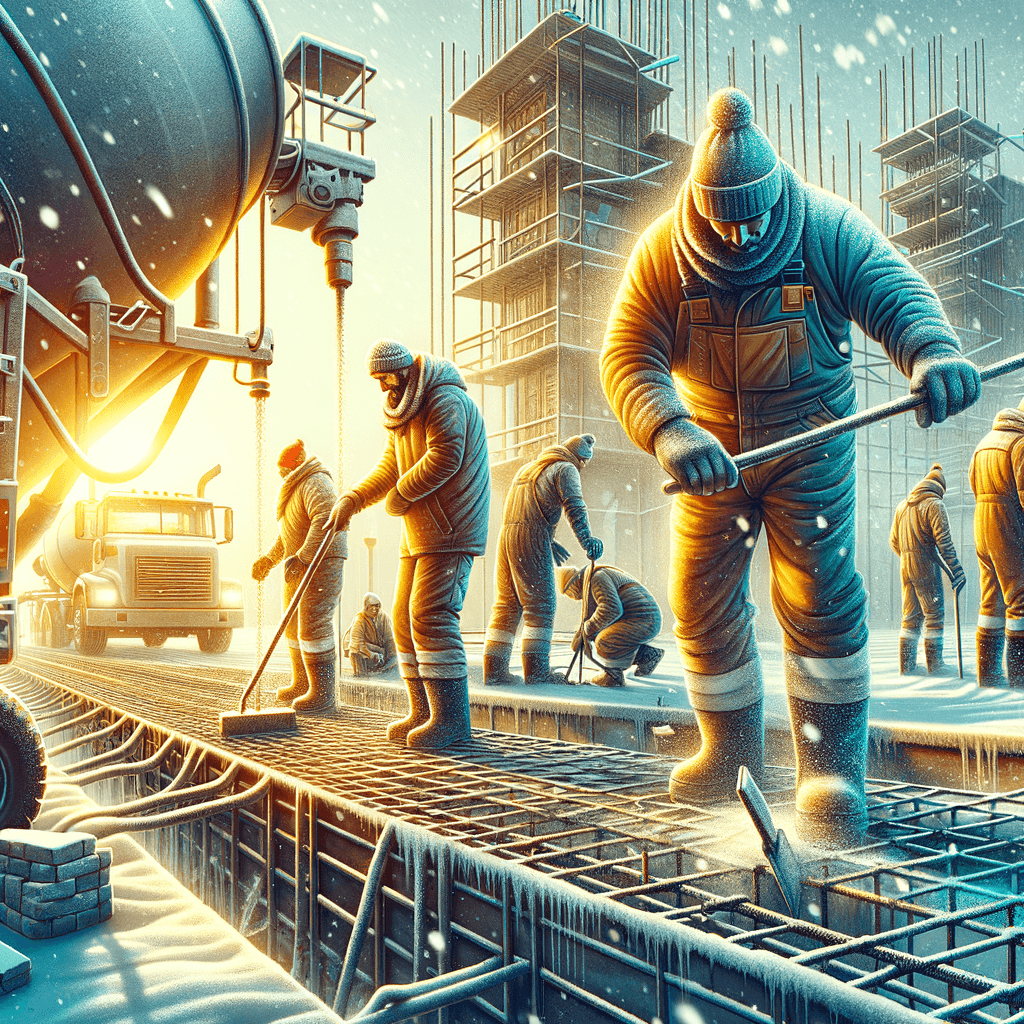

Understanding the Risks of Cold Weather Concrete Pouring

Pouring concrete in cold weather introduces a unique set of challenges that can compromise structural integrity and longevity. Low temperatures slow the hydration process, increase the risk of freezing, and can result in surface scaling, reduced strength, or delayed setting times. For contractors and property owners alike, understanding these risks is crucial to delivering durable results in winter conditions.Key Techniques for Successful Winter Concrete Placement

To mitigate the effects of cold temperatures, specialized techniques are employed to ensure proper curing and strength development. These strategies focus on maintaining optimal temperature ranges and preventing early-age freezing.- Pre-heating aggregates and mixing water to raise initial concrete temperature

- Using insulated formwork or heated enclosures to protect fresh pours

- Applying thermal blankets or heated curing blankets to retain heat

- Selecting rapid-setting or cold-weather admixtures to accelerate hydration

- Monitoring ambient and concrete temperatures throughout the curing process

“Proper planning and temperature control are the cornerstones of successful cold weather concrete work.”

Choosing the Right Admixtures and Materials

Specialized admixtures are often required when pouring concrete in suboptimal temperatures. These chemical additives can enhance workability, accelerate setting, and reduce the risk of freeze-thaw damage. Selecting the right combination of admixtures and materials is essential for achieving performance goals under winter conditions.- Accelerators (such as calcium chloride or non-chloride options) to speed up setting

- Air-entraining agents to improve freeze-thaw resistance

- Low-alkali cements to minimize expansion and cracking

- Supplementary cementitious materials (SCMs) for improved durability

Best Practices for Curing Concrete in Cold Climates

Proper curing is even more critical during winter, as inadequate moisture retention or temperature drops can cause surface defects and compromised strength. Adhering to proven best practices helps ensure that concrete achieves its design potential, regardless of the season.| Best Practice | Benefit |

| Maintain curing temperatures above 50°F (10°C) | Prevents freezing and ensures proper hydration |

| Use insulated blankets or heated enclosures | Retains heat and protects against cold snaps |

| Extend curing periods as needed | Compensates for slower strength gain in cold weather |

| Monitor moisture levels closely | Prevents surface cracking and scaling |

Common Pitfalls and How to Avoid Them

Even experienced professionals can encounter setbacks when working in cold weather. Recognizing and addressing common pitfalls can save time, money, and frustration on the jobsite.- Pouring on frozen ground, which leads to uneven curing and potential structural failure

- Neglecting to monitor temperature fluctuations during curing

- Using unapproved accelerators that may cause corrosion of reinforcement

- Failing to protect exposed surfaces from wind chill or precipitation

“Attention to detail during cold weather pours distinguishes resilient structures from those doomed to early failure.”